The bus transportation industry relies heavily on natural and synthetic rubber for various purposes including chassis, engine and suspension components.

Additional rubber assembly applications include mounts, seals, belts, bushings, O-rings, grommets, insulators, tires, wire harnesses, hoses, and other powertrain components and subsystem assemblies. Due to the slip resistant nature of rubber, it is relatively difficult to install, remove or manipulate. P-80® Lubricants provide a safe and easy way to improve assembly operations.

P-80 assists in the assembly and repair of:

-

- Air Intake Hoses

- Bearings

- Boots

- Bumpers

- Bushings

- Cooling Hoses

- Diaphragms

- Door Seals

- Engine Hoses

- Exhaust Hanger Isolators

- Grommets

- Hangers

- Hoses

- Insulators

- Mounts

- O-rings

- Plugs

- Radiator Hoses

- Rubber Moldings

- Seals

- Sleeves

- Suspension Bushings

- Transmission Cooler Lines

- Tire Mounting

- Trunk Seals

- Vibration Bushings

- Weather Stripping

- Window Seals

- Windshield Washer Hoses

- Wire Harnesses

Our Line of Lubricants

All of our P-80® Lubricants are environmentally friendly, non-hazardous, and non-flammable, making them safe for workers and most plastics, rubbers, and metals. P-80® is available in four ready-to-use industrial formulas, as well as two special formulas that are registered with the NSF as H1 lubricants approved for incidental food contact applications:

All of our P-80® Lubricants are environmentally friendly, non-hazardous, and non-flammable, making them safe for workers and most plastics, rubbers, and metals. P-80® is available in four ready-to-use industrial formulas, as well as two special formulas that are registered with the NSF as H1 lubricants approved for incidental food contact applications:

- P-80® Emulsion Temporary Rubber Assembly Lubricant: A biodegradable blend of synthetic esters and water. P-80® Emulsion provides a thin film of lubrication to significantly reduce friction. Common uses include seals, bushings, O-rings, grommets, and hoses, to name a few.

- P-80® Grip-It Quick-Drying Temporary Rubber Assembly Lubricant: A quick-drying, water-based surfactant mixture that dries tacky to help parts stay in place. P-80® Grip-It is excellent for use on pressure-tested hoses and foam grips.

- P-80® RediLube Temporary Rubber Assembly Lubricant: A biodegradable, low residue lubricant designed for use on non-porous and coated rubber surfaces. P-80® RediLube dries completely and quickly.

- P-80® THIX Temporary Rubber Lubricant Gel: A biodegradable, non-drip thixotropic gel that is ideal for overhead and vertical assembly operations.

- P-80® Emulsion IFC Temporary Rubber Assembly Lubricant & P-80® THIX IFC Temporary Rubber Lubricant Gel: Offer the same lubricating properties as P-80® Emulsion and P-80® THIX, but are specially formulated for use on parts and equipment with incidental food contact. Typical applications include assembly of appliances, pumps, and food processing equipment. Both of these P-80® IFC lubricants are certified by the NSF for use in USDA H1 applications and meet FDA regulation 21 CFR 178.3570.

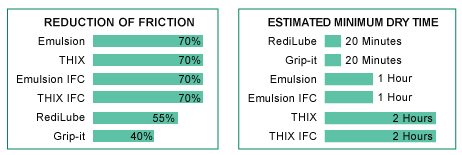

The charts below are designed to assist in determining the best P-80® formula for different applications. Each P-80® formula has unique properties designed to meet the needs of specific types of rubber and soft plastic assembly applications. For many assemblies, only one P-80® formula may resolve the assembly challenge. In other instances, more than one P-80® formula might work well. Some facilities may approve and use more than one formula depending on the application.

P-80 SPECIFICATIONS

| P-80®LUBRICANT | pH | Estimated Minimum Dry Time | Viscosity, cps @25° C | Biodegradable | Reduction of Friction |

|---|---|---|---|---|---|

| P-80® Emulsion | 7.5 – 9.5 | 1 Hour | 150 | Y | ~70% |

| P-80® Grip-It | 9.8 – 11.3 | 20 Minutes | 20 | N | ~40% |

| P-80® RediLube | 7.5 – 9.5 | 20 Minutes | 20 | Y | ~55% |

| P-80® THIX | 7.5 – 9.5 | 2 Hours | 12,000 | Y | ~70% |

INCIDENTAL FOOD CONTACT LUBRICANTS

| P-80®LUBRICANT | pH | Estimated Minimum Dry Time | Viscosity, cps @25° C | Biodegradable | Reduction of Friction |

|---|---|---|---|---|---|

| P-80® Emulsion (IFC) | 7.5 – 9.5 | 1 Hour | 150 | Y | ~70% |

| P-80® THIX (IFC) | 8.2 – 9.4 | 2 Hours | 15,000 | Y | ~70% |