Which P-80® Lubricant Is The Right Choice For My Job?

Tweet

Print

Print

What is P-80®?

P-80® is a line of temporary rubber assembly lubricants designed to decrease the installation force needed to install rubber parts, enabling them to slide easily into place.

P-80 lubricants are water-based and do not contain alcohol or petroleum distillates, so they will not cause rubber to swell, dry out or harden. P-80 does not contain silicon or other persistent ingredients, so once dry the slipping action goes away and parts stay in place.

P-80 lubricants do not contain any hazardous ingredients, making them safe for workers and the environment. Most P-80 products are biodegradable.

Emulsion? THIX? Grip-It? RediLube? … What’s the Difference?

All P-80 products provide temporary lubrication needed to reduce friction during rubber assembly to make it easier to install parts. Since each assembly application is unique, IPC has developed different P-80 formulas so workers can choose the product that will work best for their particular application.

- P-80® Emulsion is a biodegradable blend of synthetic esters and water. P-80 Emulsion provides a thin film of lubrication to significantly reduce friction

when assembling rubber or soft plastic parts.

when assembling rubber or soft plastic parts. - P-80® THIX is a biodegradable, non-drip thixotropic gel that remains where it is applied without dripping. P-80 THIX is especially useful in overhead and vertical assembly applications, and when prolonged drying times are desired.

- P-80® Grip-It provides lubricity to ease rubber assembly operations and then dries quickly to allow the natural tight fit of rubber to return. P-80 Grip-it leaves a tacky finish to help parts stay in place. Excellent for use on pressure-tested hoses.

- P-80® RediLube is a biodegradable, quick-drying, low residue formula. P-80 RediLube dries quickly and completely, making it ideal for use on parts with low surrounding air flow and on non-porous and coated rubber and soft plastic parts.

- P-80® Emulsion IFC and P-80® THIX IFC®: Both lubricants are registered with NSF for use in USDA H1 applications and meet FDA regulation 21 CFR 178.3570, which controls lubricants used for incidental food contact applications.

- P-80 Emulsion IFC: Has the same lubricating properties as P-80 Emulsion but it is specially formulated for use in incidental food contact applications. Typical applications include assembly of appliances, pumps, and food-processing equipment.

- P-80 THIX IFC: Has similar properties to P-80 THIX but is formulated for use in incidental food contact applications. P-80 THIX IFC is a thixotropic gel that remains where it is applied without dripping, making it especially useful in overhead and vertical applications.

Which P-80 is right for my application?

Each P-80 formula has unique properties designed to meet the needs of specific types of rubber and soft plastic assembly applications. Consider these factors to figure out which P-80 product will work best for your application:

- amount of lubricity required

- method of application

- PVT testing or other dry-time requirements

- type of rubber or plastic being used

- user preference

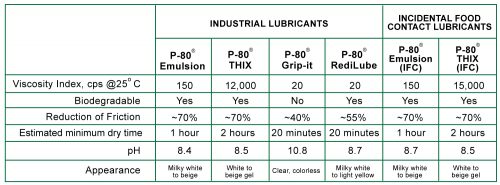

Specifications for each P-80 formula are listed in the chart below.

For some assemblies, only one P-80 formula may resolve the assembly challenge. In many instances, more than one P-80 formula might work well. The choice is often based on user preference.

Want more information about temporary rubber assembly lubricants, including how to use them and assistance in determining which P-80 formula will best serve your needs? Download IPC’s free P-80 webinar. Or contact our technical team to help you find the best solution for your assembly needs.

Tweet

Print

Print