Go Easy with P-80® for Appliance Assembly

Tweet

Print

Print

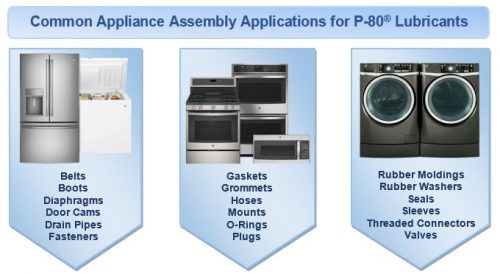

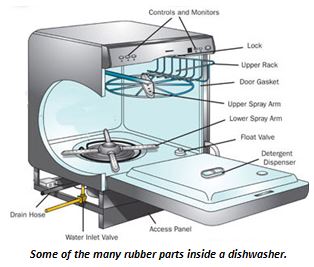

Dishwashers, washers and dryers, refrigerators, mixers, blenders, and many other appliances are composed of numerous rubber and soft plastic parts. Hoses, O-rings, seals, grommets, plugs, belts and valves are just some of the many parts that can be found in common household appliances.

Rubber’s slip resistant nature can make appliance assembly difficult. Using a temporary rubber lubricant during assembly can make appliance manufacturing much easier. Maintenance and repair of common appliances is also less difficult when temporary assembly lubricants are used to replace belts, O-rings, hoses and seals.

P-80® temporary rubber assembly lubricants significantly reduce friction helping rubber parts slide easily into place.

P-80® lubricants are water-based, and do not contain alcohol or petroleum distillates so they will not cause rubber to dry out or harden. P-80® does not contain silicon or other persistent ingredients, so once dry you have a tight fitting part.

Advantages of using P-80® lubricants:

- Reduce the force required for installation

- Increase production rates

- Reduce part breakage and rejects

- Allow for closer fitting part design

- Reduce risk of musculoskeletal and slippage related injuries

Interested in learning more? Download a case study detailing how one major appliance manufacturer benefited from using P-80® to reduce drop test failures.

Stop struggling with rubber parts during appliance repair and assembly. Contact IPC to discover how you can benefit from using P-80® temporary lubricants for appliance assembly and repair.

Tweet

Print

Print