Solve Hydraulic Line Assembly Problems With P-80® THIX

Tweet

Print

Print

A worldwide crane manufacturer experienced hydraulic system issues, including contamination, rolled O-rings, leaks, and line shut-downs resulting from numerous false-positive leak detections. Once they began using P-80® THIX for assembly they were able to eliminate false positive hydraulic leaks and contamination, allow easier thread starts and aligned joint assemblies, and achieve torque specifications.

What is P-80® THIX?

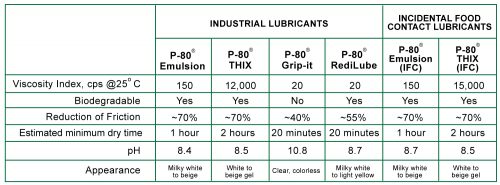

P-80 THIX is a biodegradable temporary assembly lubricant that eases installation of tight-fitting rubber and plastic parts by reducing the force needed for insertion. Once assembly is complete, the lubricant dries and the part stays in place. Since THIX is a water-based, thixotropic gel, it stays where it’s put without dripping. THIX does not contain any alcohol or petroleum distillates, so it will not cause rubber to swell, dry out or harden, nor does it contain any hazardous ingredients, making it safe for workers and the environment.

What Was Happening at the Crane Manufacturer’s Plant?

The crane manufacturer was using multiple petroleum-based lubricants for the assembly of hydraulic hoses and thread starts. These lubricants eased the assembly of the hydraulic lines and facilitated thread starts, but, if not applied meticulously, slowed production, increased cost of quality, and increased the amount of rework needed. Over-application of these lubricants caused residue to remain in and around hydraulic lines attracting dirt, contaminating hydraulic systems, fluorescing brightly during black light leak inspections – leading to false positive results, and reducing installation torque over time. When used sparingly, the lubricants caused leaks from rough thread starts, rolled O-rings, friction-related damage, misaligned parts, and low installation torques. They also had frequent line shut-downs because of many false-positive leak detections.

P-80 THIX to the Rescue

A team of design engineers, material engineers and hydraulic line assemblers worked together to find a solution. P-80 THIX was trialed for assembly of hydraulic lines and coating of threads for wet torque starts.

Since THIX is a water-based emulsified thixotropic gel, the volume applied was not critical. Once applied, THIX remained in place regardless of the part’s orientation. The gel as a whole reduced assembly friction by 70% thereby eliminating rolled O-rings and misaligned parts. Installation torques were achieved consistently. After assembly, THIX began to evaporate and lose its lubrication – leaving at most a negligible residue, which will not attract dirt or contaminate the hydraulic system, will not fluoresce, and cannot reduce torque over time.

The crane manufacturer experienced an immediate improvement in cost of quality and on-time delivery metrics. As a result, THIX has been implemented throughout the entire assembly floor and is currently being trialed at other locations worldwide.

Read the full case study and learn more about using P-80 THIX for assembly and maintenance of construction equipment.

Want to try P-80 for your assembly or repair needs? Request a free sample.

Contact IPC’s technical team to help you find the best solution for your assembly needs.

Tweet

Print

Print