5 Reasons Why P-80 Is the Best O-Ring Lubricant

Tweet

Print

Print

Remember the last time you had to install an O-ring? Maybe you were assembling new equipment or repairing a pump. Regardless of the type of equipment involved, unless you used an O-ring lubricant chances are you may have struggled with the installation. Common O-ring installation problems include tearing, twisting, turning, pinching and overstretching. Incorrectly installed O-rings may cause leaks which can damage parts and equipment. O-rings that are properly installed can prevent leaks and increase part life.

Common O-ring installation problems include tearing, twisting, turning, pinching and overstretching. Incorrectly installed O-rings may cause leaks which can damage parts and equipment. O-rings that are properly installed can prevent leaks and increase part life.

Avoid Problems By Using An O-Ring Lubricant

Using O-ring lubricants during installation helps avoid these problems. Applying a thin film of lubricant to an O-ring will help it slide into place easily.

Advantages of Using O-ring Lubricants:

- Reduce force needed for installation

- Accelerate assembly processes

- Achieve closer fits by helping to properly seat the O-ring

- Aid automated assemblies

- Improve product performance and reduce failures

- Increase production rates

- Help avoid worker injuries

Types of O-Ring Lubricants:

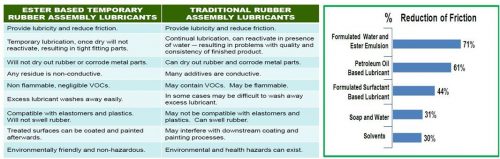

Common O-ring lubricants include soap and water, petroleum distillates, solvents and ester-based products. While all will provide lubrication to help install O-rings, some of these choices may cause damage to the rubber or present safety concerns.

Petroleum-based products can cause rubber to swell or dry out. Solvents provide poor lubrication, contain high VOCs, may be flammable, and pose possible health risks. Soap and water, while safe, provide inconsistent, nominal lubrication and may reactivate when wet causing problems after assembly.

Ester-based lubricants provide excellent reduction in friction, offer temporary lubrication, and are safe for both workers and the environment.

Here is a comparison of some common lubricant choices:

5 Reasons Why P-80 Is the Best O-Ring Lubricant

P-80 Temporary Assembly Lubricants are the ideal choice for installing O-rings.

- Reduce Installation Force:

Applying a thin film of P-80 to O-rings reduces the force needed for installation, allowing them to slide easily into place. - Reduce Part Damage:

Without proper lubrication, O-rings can tear or twist during installation leading to improper part alignment. Misaligned parts can result in part failure or safety issues. O-rings are less likely to get damaged while using P-80 lubricants. Additionally, P-80 lubricants do not contain any petroleum so they won’t cause O-rings to swell or dry out. - Speed Up Production:

Applying P-80 lubricants to O-rings makes them slippery, so they can easily slide into place. After the P-80 dries, the lubricity goes away and the O-rings maintain a tight fit. The assembly process becomes more productive because it is easier and quicker. - Reduce Worker Injuries:

P-80 lubricants reduce the insertion force needed to install O-rings making it easier for workers to push O-rings into place. The occurrence of musculoskeletal, slippage and repetitive stress related injuries that can be caused by using too much force during installation is reduced. - Protect The Environment:

P-80 lubricants are environmentally friendly, non-hazardous, and non-flammable, making them safe for workers and most plastics, rubbers, and metals. In fact, most P-80 products are biodegradable.

Seeing Is Believing

See for yourself just how well P-80 Temporary Assembly Lubricants work for installing O-rings.

In the first video, the force needed to install an O-ring without using P-80 is 447.1 Newtons. P-80 is used in the second video to install the same O-ring. The force needed to install the O-ring with P-80 is 43.4 Newtons.

O-ring installation without lubrication:

O-ring installation using P-80:

The results are dramatic. In this example, P-80 reduced the force needed to install the O-ring by 403.7 Newtons.

Installing O-rings doesn’t have to be a struggle. Use a temporary assembly lubricant to aid the process and protect the part.

Have an O-ring you need to install? Request a free sample for testing!

Tweet

Print

Print