Vroom…Motorcycle Assembly Just Got Easier

Tweet

Print

Print

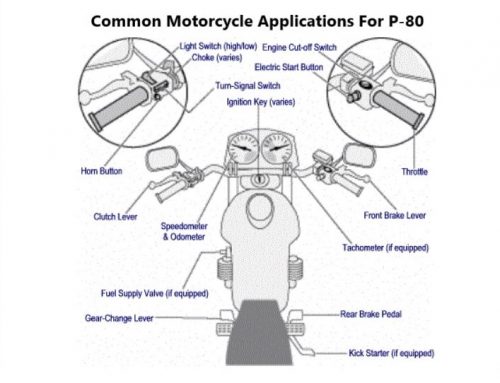

Motorcycles and power sports vehicles are full of rubber parts. Assembling these parts can be an arduous task. If you have ever struggled with installing bushings, hoses, engine oil seals, handle grips or footrests, you know firsthand just how difficult it can be to install these rubber parts.

Rubber is naturally slip resistant, making it difficult to work with. Trying to install, remove or manipulate tight fitting rubber components can be a real challenge. Parts that are improperly aligned or installed may result in performance or safety issues. Using a temporary assembly lubricant makes rubber installation easier and helps avoid these types of problems.

P-80® Temporary Rubber Assembly Lubricants decrease the force needed to install rubber parts, enabling them to slide easily into place. Once dry, P-80 stops lubricating and parts remain in place, resulting in a tight fit.

P-80 is used by many motorcycle manufacturers, suppliers and repair shops to ease the force needed to install rubber parts such as bushings, hoses, O-rings, belts, gaskets and grips.

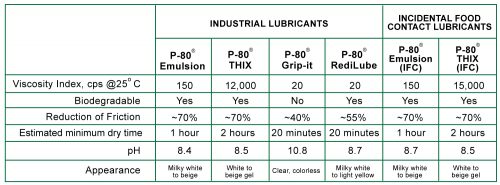

P-80 lubricants are water-based and do not contain alcohol or petroleum distillates, so they will not cause rubber to swell, dry out or harden. P-80 does not contain silicon or other persistent ingredients, so once dry the slipping action goes away resulting in a tight fit. P-80 lubricants do not contain hazardous ingredients, making them safe for workers and the environment; most are biodegradable.

What are the Benefits of Using P-80 Temporary Assembly Lubricants?

Reduce Installation Force

A thin film of lubricant applied to a part fills in any gaps, holes, or spaces between two separate surfaces, allowing them to slide across each other. By reducing the friction between the two surfaces, rubber parts slide into place easily.

Achieve Closer Fits

The force needed to install parts when a lubricant is used is greatly reduced, so engineers can design lower tolerance parts. Since the lubrication is only temporary, once dry, the parts stay in place resulting in a tight fit.

Improve Product Performance and Reduce Failures

Improper part alignment can lead to part failure and safety issues. Using lubricants is one way to ensure that mated parts are properly installed and will work as anticipated.

Increase Production Rates and Accelerate Assembly Processes

Pairing the optimal lubricant with the right application technique speeds up production. An increase in lubricity, even by small amounts, is greatly appreciated by line operators required to maintain strict cycle times.

Help Avoid Injuries

Assembly lubricants ease the installation process of many parts. Workers can more easily push parts into place, reducing the amount of musculoskeletal, slippage, and repetitive stress related injuries that can be caused by using too much force to insert a rubber part.

The next time you’re having trouble installing suspension bushings, pushing a hose into place or installing handle grips try using P-80 and see how much easier the job becomes. Temporary lubricants are ideal for motorcycle assembly and repair because they reduce friction without damaging parts.

Want to try P-80 for your motorcycle and power sports vehicle assembly or repair needs? Request a free sample.

Contact our technical team to help you find the best solution for your assembly needs.

Tweet

Print

Print