P-80®: A Safe and Easy Assembly Lubricant That Improves Automotive Assembly Operations

An automotive assembly lubricant can counteract rubber’s non-slip properties. Without a quality assembly lubricant, the automotive assembly process can be very difficult. In addition without an assembly aid, tight-fitting rubber components can cause production to slow down. Quality and safety standards will also slip. The P-80® line is specially formulated to provide temporary assembly lubrication. As a result, rubber automotive assembly parts are easier to install, remove, or otherwise manipulate.

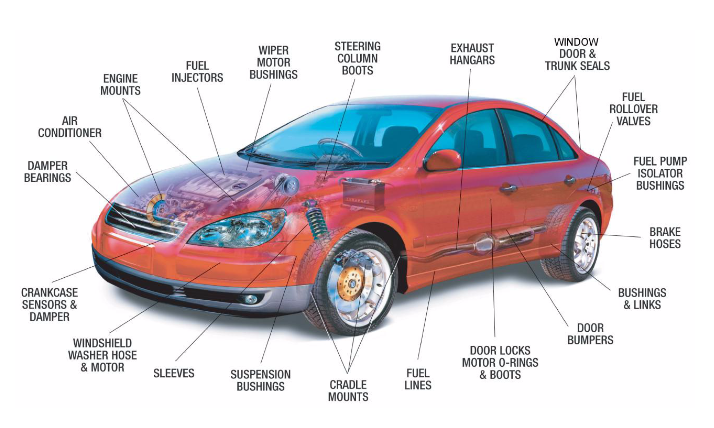

P-80 assists in the assembly and repair of:

- Air Intake Hoses

- Bearings

- Boots

- Bumpers

- Bushings

- Cooling Hoses

- Diaphragms

- Door Seals

- Engine Hoses

- Exhaust Hanger Isolators

- Grommets

- Hoses

- Insulators

- Mounts

- O-rings

- Plugs

- Radiator Hoses

- Rubber Moldings

- Seals

- Sleeves

- Suspension Bushings

- Transmission Cooler Lines

- Tire Mounting

- Trunk Seals

- Vibration Bushings

- Weather Stripping

- Window Seals

- Windshield Washer Hoses

- Wire Harnesses

Benefits of Our Line of Automotive Assembly Lubricants

There are many benefits of our P-80® line of lubricants. First, all of our P-80® Lubricants are environmentally friendly, non-hazardous, and non-flammable. As a result, this makes our lubricants safe for workers. In addition, it will not harm most plastics, rubbers, or metals. Finally, P-80® is available in four ready-to-use industrial formulas. Also available are two special formulas that are registered with the NSF as H1 lubricants approved for incidental food contact applications:

There are many benefits of our P-80® line of lubricants. First, all of our P-80® Lubricants are environmentally friendly, non-hazardous, and non-flammable. As a result, this makes our lubricants safe for workers. In addition, it will not harm most plastics, rubbers, or metals. Finally, P-80® is available in four ready-to-use industrial formulas. Also available are two special formulas that are registered with the NSF as H1 lubricants approved for incidental food contact applications:

- P-80® Emulsion Temporary Rubber Assembly Lubricant: A biodegradable blend of synthetic esters and water. Our P-80® Emulsion provides a thin film of lubrication to significantly reduce friction. Common uses include seals, bushings, O-rings, grommets, and hoses, to name a few.

- P-80® Grip-It Quick-Drying Temporary Rubber Assembly Lubricant: A quick-drying, water-based surfactant mixture that dries tacky to help parts stay in place. Our P-80® Grip-It is excellent for use on pressure-tested hoses and foam grips.

- P-80® RediLube Temporary Rubber Assembly Lubricant: A biodegradable, low residue lubricant designed for use on non-porous and coated rubber surfaces. You will find that P-80® RediLube dries completely and quickly.

- P-80® THIX Temporary Rubber Lubricant Gel: A biodegradable, non-drip thixotropic gel that is ideal for overhead and vertical assembly operations.

- P-80® Emulsion IFC Temporary Rubber Assembly Lubricant & P-80® THIX IFC Temporary Rubber Lubricant Gel: Offer the same lubricating properties as P-80® Emulsion and P-80® THIX, but are specially formulated for use on parts and equipment with incidental food contact. Typical applications include assembly of appliances, pumps, and food processing equipment. Both of these P-80® IFC lubricants are certified by the NSF for use in USDA H1 applications and meet FDA regulation 21 CFR 178.3570.

P-80 PROPERTIES

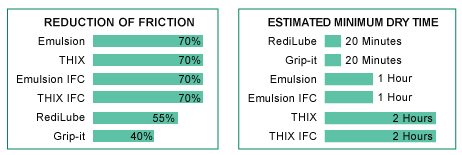

The charts below are designed to assist in determining the best P-80® formula for different applications. Each P-80® formula has unique properties. These properties are designed to meet the needs of specific types of rubber and soft plastic assembly applications. For many assemblies, only one P-80® formula may resolve the assembly challenge. In other instances, more than one P-80® formula might work well. Also, some facilities may approve and use more than one formula depending on the application.

P-80 SPECIFICATIONS

| P-80®LUBRICANT | pH | Estimated Minimum Dry Time | Viscosity, cps @25° C | Biodegradable | Reduction of Friction |

|---|---|---|---|---|---|

| P-80® Emulsion | 7.5 – 9.5 | 1 Hour | 150 | Y | ~70% |

| P-80® Grip-It | 9.8 – 11.3 | 20 Minutes | 20 | N | ~40% |

| P-80® RediLube | 7.5 – 9.5 | 20 Minutes | 20 | Y | ~55% |

| P-80® THIX | 7.5 – 9.5 | 2 Hours | 12,000 | Y | ~70% |

INCIDENTAL FOOD CONTACT LUBRICANTS

| P-80®LUBRICANT | pH | Estimated Minimum Dry Time | Viscosity, cps @25° C | Biodegradable | Reduction of Friction |

|---|---|---|---|---|---|

| P-80® Emulsion (IFC) | 7.5 – 9.5 | 1 Hour | 150 | Y | ~70% |

| P-80® THIX (IFC) | 8.2 – 9.4 | 2 Hours | 15,000 | Y | ~70% |