Reclaiming Water To Maintain Future Economic Growth

Tweet

Print

Print

The Challenge

How do you provide a consistent, high quality supply of water when you have a large volume ethanol distiller located in your backyard? The city of Fargo, ND came up with the perfect solution: reclaim water through the municipal wastewater treatment plant!

The History

The History

The wastewater treatment plant in Fargo, North Dakota has an auxiliary effluent re-use facility constructed specifically to produce reverse osmosis quality water destined for ethanol production. A local corn to ethanol distiller, Tharaldson Ethanol, requires approximately 1,000,000 gallons (3.8 million liters) of reverse osmosis water per day above the wastewater treatment plant’s normal processing volumes. Fargo’s wastewater control systems manager, Jeff Hoff, manages the effluent re-use facility to ensure this additional volume is met on a daily basis.

The Problem

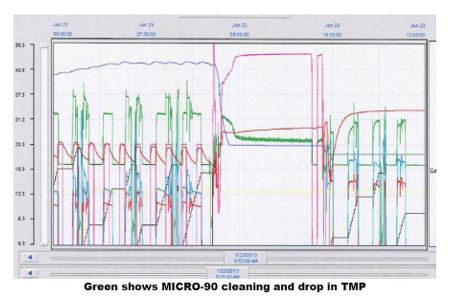

A key component of the effluent re-use facility is the ultra-filtration process, which uses 0.4μ polyvinylidene difluoride (PVDF) membranes with an upper pH limit of 10.0. These membranes are fouled primarily with petroleum sulfonates and bacterial secretions. Particularly in cold weather, the upstream BOD step has frequent “upsets,” where the bacteria die and secrete a water soluble foulant that adheres strongly to the PVDF polymer and significantly increases the trans-membrane pressure (TMP). These “upsets” must be resolved quickly to ensure a plentiful supply of pure water.

The Test

In order to determine the optimal cleaning regimen to resolve these upsets, Jeff systematically evaluated the performance of twenty different cleaners and hundreds of different combinations and concentrations, including commonly used commodities and many formulated membrane cleaners.

The Solution

Jeff discovered that Micro-90®, a formulated cleaner from International Products Corporation (IPC), stood out because it performed better than all of the commodities and other formulated membrane cleaners, particularly on the bacterial secretions. What Jeff found most impressive is that this formulated cleaner worked effectively without the use of phosphates, silicates, and strong alkalis, at a membrane compatible pH of only 9.5, and at a 0.3 percent concentration.

The Product

Micro-90® is a mild, yet powerful, multipurpose, alkaline cleaning concentrate that is used for membrane cleaning as well as in laboratories, industrial applications, and critical cleaning processes. A unique chelating detergent, Micro-90® contains anionic and non-ionic ingredients which combine to produce a variety of cleaning actions. Micro-90® is compatible with UF, RO, Ceramic and NF Systems.

The Long-Term Success

This same formulation has been in use at Fargo’s effluent re-use facility since October 2010. Some of the original PVDF membranes are still used and continue to see significant TMP drops after cleaning. Although the bacterial upsets cannot be prevented, their fouling can be resolved in a predictable manner with the use of this formulated product.

The engineers at the facility recognize that using Micro-90® for regularly scheduled preventative maintenance and cleaning of the membranes proves to be an effective, safe, and economical method of keeping the plant running efficiently and the water flowing continually. Based on its effectiveness, safe profile, compatibility and economical cost per use, they have recommended Micro-90® to design engineers at similar effluent re-use facilities.

Read more about cleaning filter membranes here:

How To Choose the Proper Membrane Cleaner

Make Your Membranes Last…A Simple 10 Step Guide

Tweet

Print

Print